Image 1 of 7

Image 1 of 7

Image 2 of 7

Image 2 of 7

Image 3 of 7

Image 3 of 7

Image 4 of 7

Image 4 of 7

Image 5 of 7

Image 5 of 7

Image 6 of 7

Image 6 of 7

Image 7 of 7

Image 7 of 7

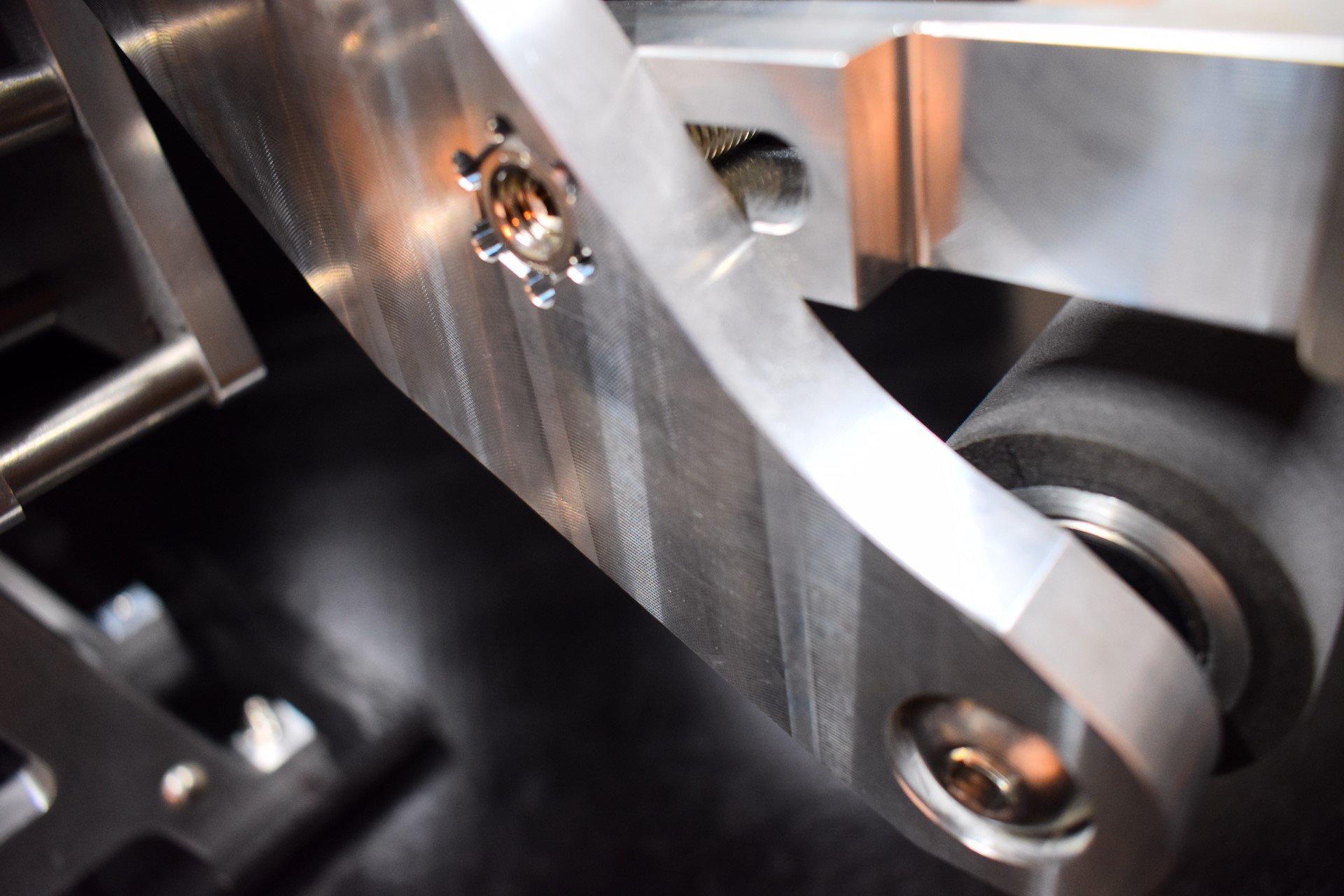

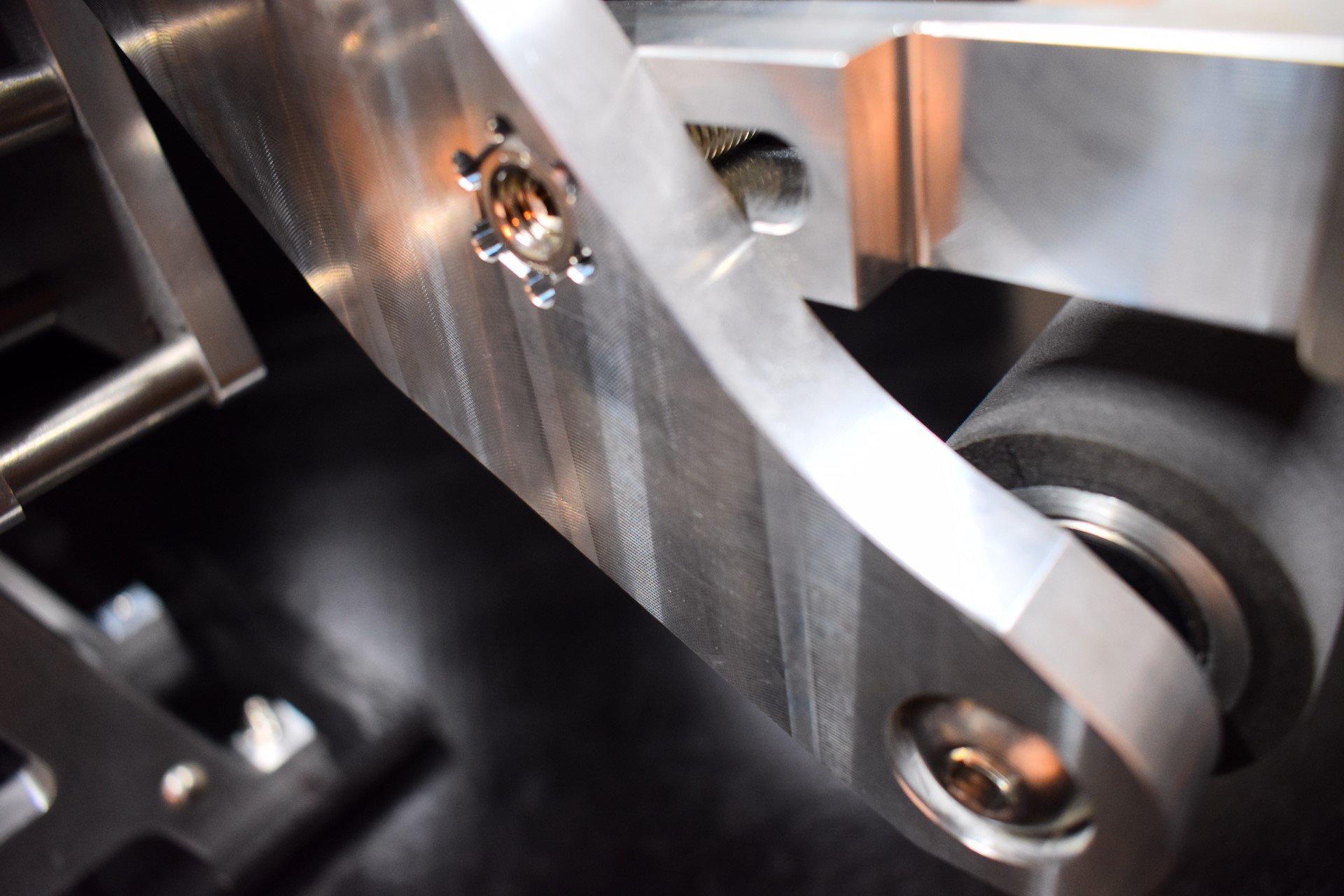

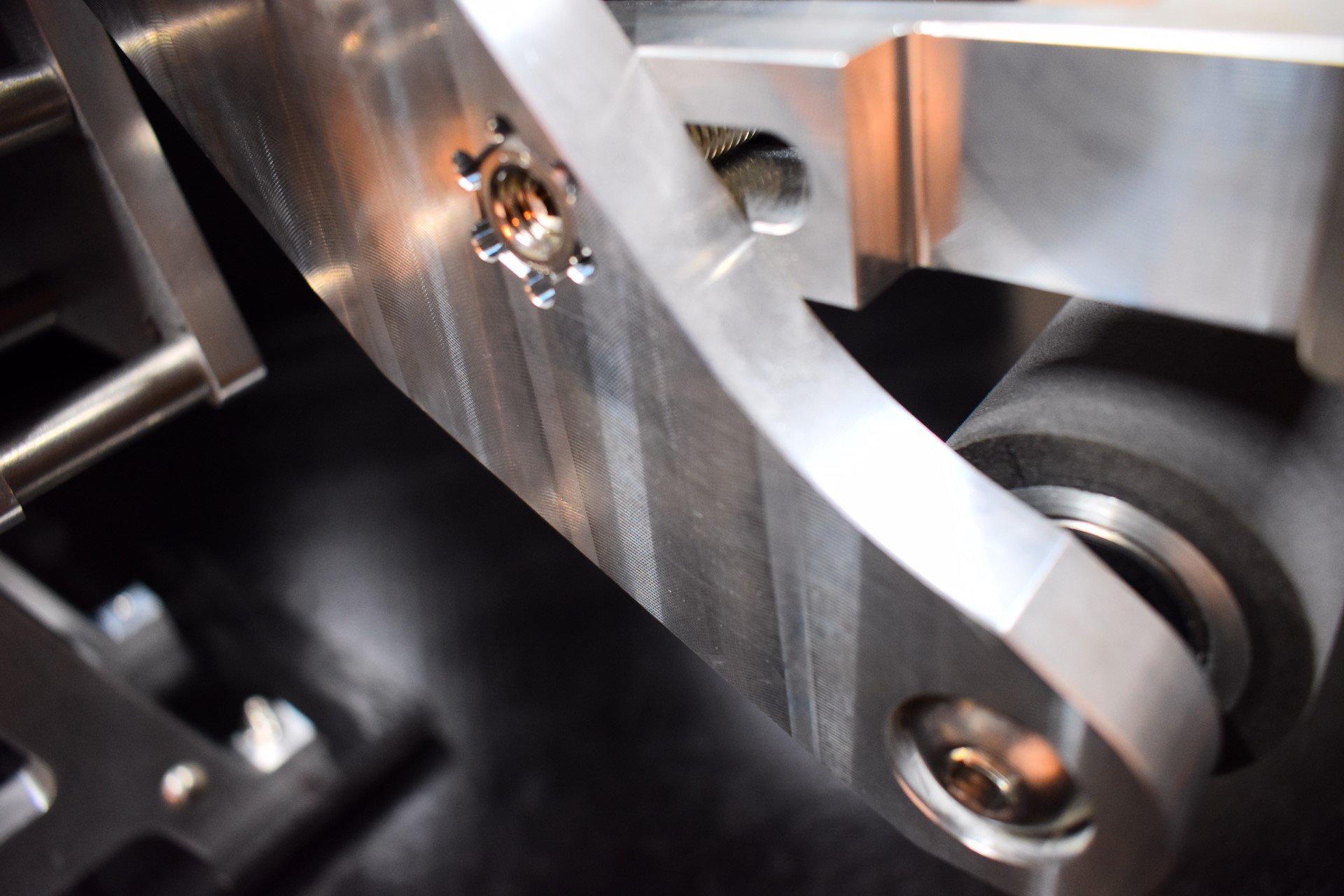

Contender Quick Change Platen System

A Contender exclusive design, this tool arm and platen system is the most modular and robust attachment system available for a 2x72 belt grinder.

A Contender exclusive design, this tool arm and platen system is the most modular and robust attachment system available for a 2x72 belt grinder.

A Contender exclusive design, this tool arm and platen system is the most modular and robust attachment system available for a 2x72 belt grinder.

This system is designed to use a single tool arm that allow for quickly mounting various attachments to it. The included platen mounts to the tool arm via a taper locking/locating pull stud. This makes a very solid, compact and square connection. The taper lock helps absorb vibrations as well. The pull studs are pulled tight with the quick adjust locking handle. Simply slide the attachment mounted pull stud into the arm and screw the handle down snug. With this system there is no need to ever remove the tool arm from the grinder. The attachments are much more compact and easy to store. This is critical when space is limited. Additional pull studs allow for quickly mounting contact wheels, small wheel attachment and any other attachment that can be mounted with a 1/2 inch bolt.

The platen frame is fully machined, billet aluminum. It used quick change brackets for mounting and quickly changing out different platens in seconds. The frame has witness lines engraved for quickly squaring up the platen to the machine. A spring plunger mounted in the tool arm allows the platen to be tipped at different angles quickly. It can also be retracted to allow any angle you may desire.

The platen comes standard with two rubber contact wheels with internal spacers for increased bearing life. The platen can also be quickly converted to a rotary platen. (accessories sold separately)

One of the best features of this platen system are the adjustable Cam Arbors the pulleys are mounted on. These arbors can be individually adjusted by turning the mount bolts to the right (to prevent loosening). By doing this the tracking of the belt can be easily manipulated. This manipulation allows the user to quickly fine tune the tracking in both forward and reverse directions. Any belt can by straightened out in a couple seconds. This is extremely important when doing final plunge grinds or when sharpening blades on the grinder. The arbors are cnc turned from solid stainless steel shaft.